Phone Number

91-9927019951

Our Products

Contact Us for Help

Contact with us through our representative or submit a business inquiry online.

CONTACT USTableware Moulding Machine

Bagasse Pulp Molded Tableware

Manufacturing 100% biodegradable and compostable tableware is the need of the hour. With the help of our bagasse pulp molding machines, we drive pulp mill owners to eliminate the single-use plastic by producing eco-friendly tableware and free our "Mother Earth" from hazards and harmful pollutants.

With time, the industries grew and so did the pollution and other hazardous problems. The need for making environment friendly products is unavoidable. Bagasse Fiber Molding Machine is a solution to a major field of tableware. Amar’s experience in paper making technologies provide energy efficient and sustainable solutions to convert the residual agro fiber into something new. We help you to set up complete projects to produce molded bagasse fiber pulp products.

How is fiber pulp molded tableware made from bagasse?

The non-wood pulp of sugarcane bagasse, rice straws, bamboo, wheat straw, etc. is bought and converted into pulp slurry. Waterproof and oil proof additives are added to it. Then, this pulp slurry is sent to the pulp slurry chest. The pulp stock supply chest moves the pulp continuously to the pulp forming machines.

Forming is the key process in the tableware production line. The process is quantitatively pulp supply using deposition method, back flushing air supply, vacuum dewatering, and forming.

In our Semi-Automatic Molded Fiber Production Machine, the pulp is molded into different products like plates, bowls, trays, etc.

The machines are developed using advanced technologies to eliminate holes, uneven thickness during production to reduce defective goods.

The semi-finished product will be moved to the hot press station for mold drying. The product taken out from the hot press undergo through an edge cutting machine where the extra edge will be trimmed.

After this process, the product is ready for quality check. Here, all products are checked for their shape, size, and durability. After the quality check, the product is passed on to the counting division where it is counted and sent for packaging.

Applications

The semi-auto tableware machine is mainly applied for producing pulp molding one time use tableware, premium egg packaging, medical care items, high end industrial packaging products and so on.

Advantages

Save initial capital investment comparing to fully automatic machines To give advantage of cheaper labor areas Lower cost of mold set compared to automatic machines Simple and flexible operations and maintenance

Specifications

| Structure | Easy to handle 3Pcs. Structure 1. Forming Stage x1 in the middle 2. Hot pressing Stage x2 on the two sides |

| Platen Size | 1000mm x 950 mm |

| Forming Type | Top Forming |

| Heating Type | Thermal Oil or Electric |

| Max. Pressure | 40 Ton, HydroPneumatic Cylinders |

| Max. Product Height | 80 mm |

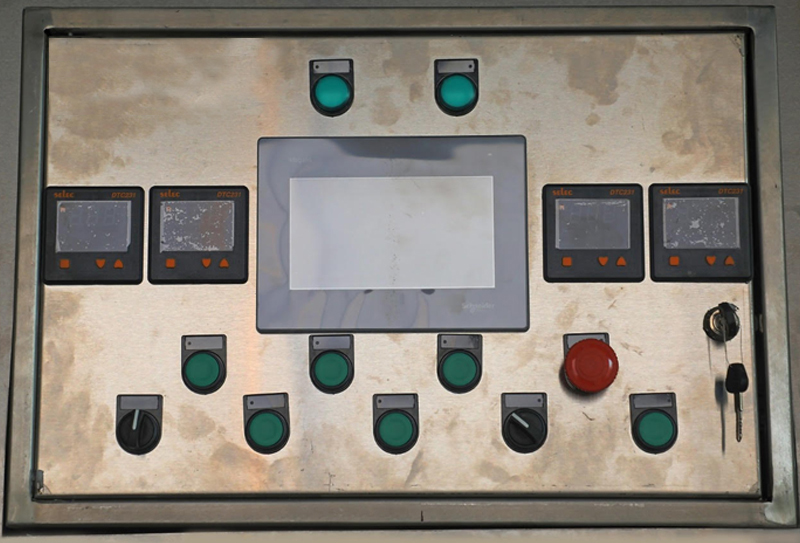

| Control By | PLC + Touchscreen |

| Designed Capacity | 400 - 500 KG/Day |

| Remarks | * All Parts in contact with pulp will be of S.S. 304 * Complete S.S.304 covers * Rigid stress relieved M.S. square pipe frame |